Recycling of Rubber

Practical Action

In developing countries, there is a culture of reuse and recycling. Waste collectors roam

residential areas in large towns and cities in search of reusable articles. Some of the

products that result from the reprocessing of waste are particularly impressive and the levels

of skill and ingenuity are high. Recycling artisans have integrated themselves into the

traditional market place and have created a viable livelihood for themselves in this sector. The

process of tyre collection and reuse is a task carried out primarily by the informal sector.

Tyres are seen as being too valuable to enter the waste stream and are collected and put to

use.

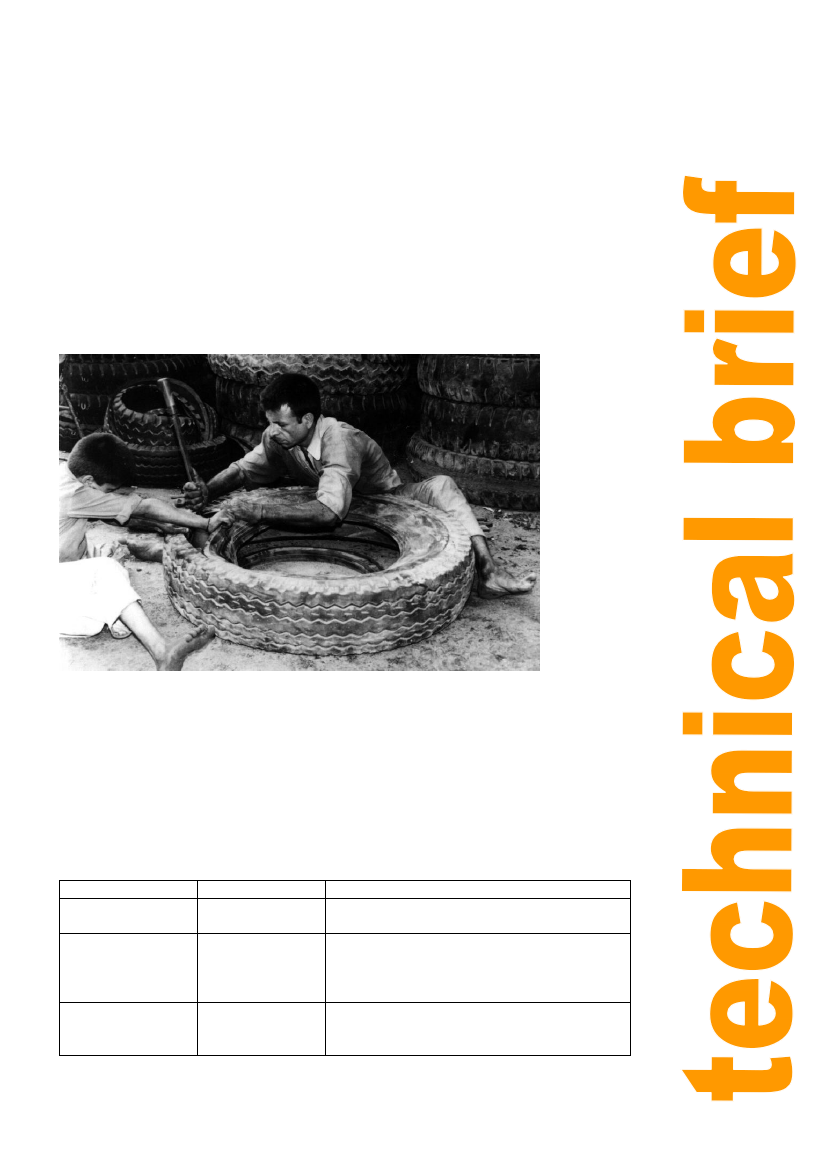

In Karachi, Pakistan, for example, tyres are collected and cut into parts to obtain secondary

materials which can be put to good use. The beads of the tyres are removed and the rubber

removed by burning to expose the steel. The tread and sidewalls are separated – the tread is

cut into thin strips and used to cover the wheels of donkey carts, while the sidewalls are used

for the production of items such as shoe soles, slippers or washers (WAREN Report).

Figure 2: Manual Separation of the Tread from the Sidewalls, Karachi, Pakistan

Photo: PCSIR – WASTE

Recovery of rubber

Recovery Alternatives

There are many ways in which tyres and inner tubes can be reused or reclaimed. The waste

management hierarchy dictates that re-use, recycling and energy recovery, in that order, are

superior to disposal and waste management options. This hierarchy is outlined in Table 3

below.

Kind of recovery

Product reuse

Material reuse

Repair

Physical reuse

Physical

Recovery process

Retreading

Regrooving

Use as weight

Use of form

Use of properties

Use of volume

Tearing apart

Cutting

Processing to crumb

4